Why?

Kraft delignification is the core of the currently dominating technology used to separate the main wood components form each other and is, as such, also seen as an embryo of future forest-based biorefineries with high requirements on material and energy efficiency. While the chemical reactions carrying out the separation are relatively well-investigated, understanding of the underlying mass transfer (of both cooking chemicals and solubilized wood components) through a wood chip is still limited, especially considering the directional and morphological dependence of the mass transport:

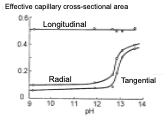

– mass transport in the longitudinal direction takes place predominantly through the lumen (cell cavities developed to conduct a liquid) and is relatively efficient

– in the radial and tangential direction it occurs mainly through the pit membranes (small channels connecting the cells) and pores in the cell walls creared during pulping, with significantly smaller efficient area and a higher mass transfer resistance.

Detailed insight in these phenomena is a prerequisite for a proper mechanistic understanding and further improvement of a complex sequence of chemical and physical steps governing the outcome of this important process.

Aim and objectives

The goal of this project is to investigate the different components of mass transfer through a wood chip by separately studying its contributions from different directions in the wood tissue. Sealing the critical conducting surfaces of a wood chip prior to pulping is one way of blocking the mass transfer in a selected direction and thus separating different mass transfer contributions.

Methodology

The focus of the project will be to:

- Develop a sealing methodology for the chips that will enable pulping without interference of the sealing material

- Investigate the pulping performance of the wood chips with well-defined geometry and selectively sealed conducting surfaces:

- The A & B surfaces will be sealed

- The C surfaces will be sealed

Prerequisites

The applicants should preferably have a background in chemical engineering, wood chemistry and process technology with a collaborative approach. The project can be performed in pair.

Project start

September 2023 or according to agreement

Supervisors:

TomasVikström, tomas.viktrom@valmet.com

Merima Hasani, merima.hasani@chalmers.se